Barrier Glands - CCG

Problems With Cable Construction

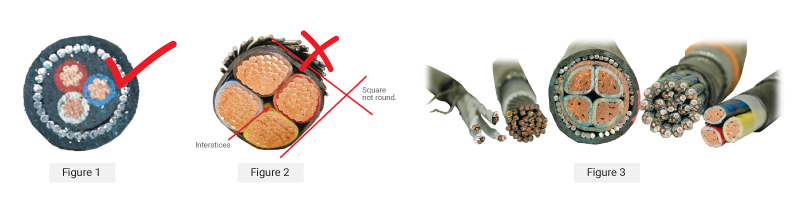

To comply with the installation codes of practice for hazardous areas, cable glands using elastomeric sealing rings should only be used on cables that are substantially round, compact with extruded bedding, and have non-hygroscopic fillers, such as Figure 1. For all other cables sch as Figure 2 and 3, Barrier glands should be used.

When To Use Barrier Glands

IEC 60079-14: Explosive atmospheres – Part 14; Electrical installation design, selection and installation of equipment, including initial inspection.

Prescribes the selection of electrical equipment in hazardous areas. Knowledge of this Standard is imperative when selecting cables and cable glands for use in hazardous areas, and merely referring to the product certification is not enough.

IEC 60079-14 clause 7.4. “Selection of Cable” states. “For nominally circular cables, where there is an inner sheath provided in the cable on which a sealing ring is to be applied this shall be nominally circular to maintain the Type of Protection when fitted with a cable entry device selected in accordance with 7.5. In cases where due to the application, gas or vapour migration could occur through the cable, and the cable leads to a non-hazardous area or between different zones, then the cable construction (for example the compactness) shall be taken into account. Appropriate control measures shall be considered, for example the use of resin joints or cable entry devices which seal around individual conductors.” i.e. a barrier gland.

Ex d Equipment:

IEC 60079-14 Clause 7.5.7 – “Cable entry device for Type of Protection “d”” states:

…the cable entry system shall comply with one of the following:

- cable entry devices which seal around individual conductors (barrier cable entry devices) in compliance with IEC 60079-1, and having an Ex Equipment certificate; or

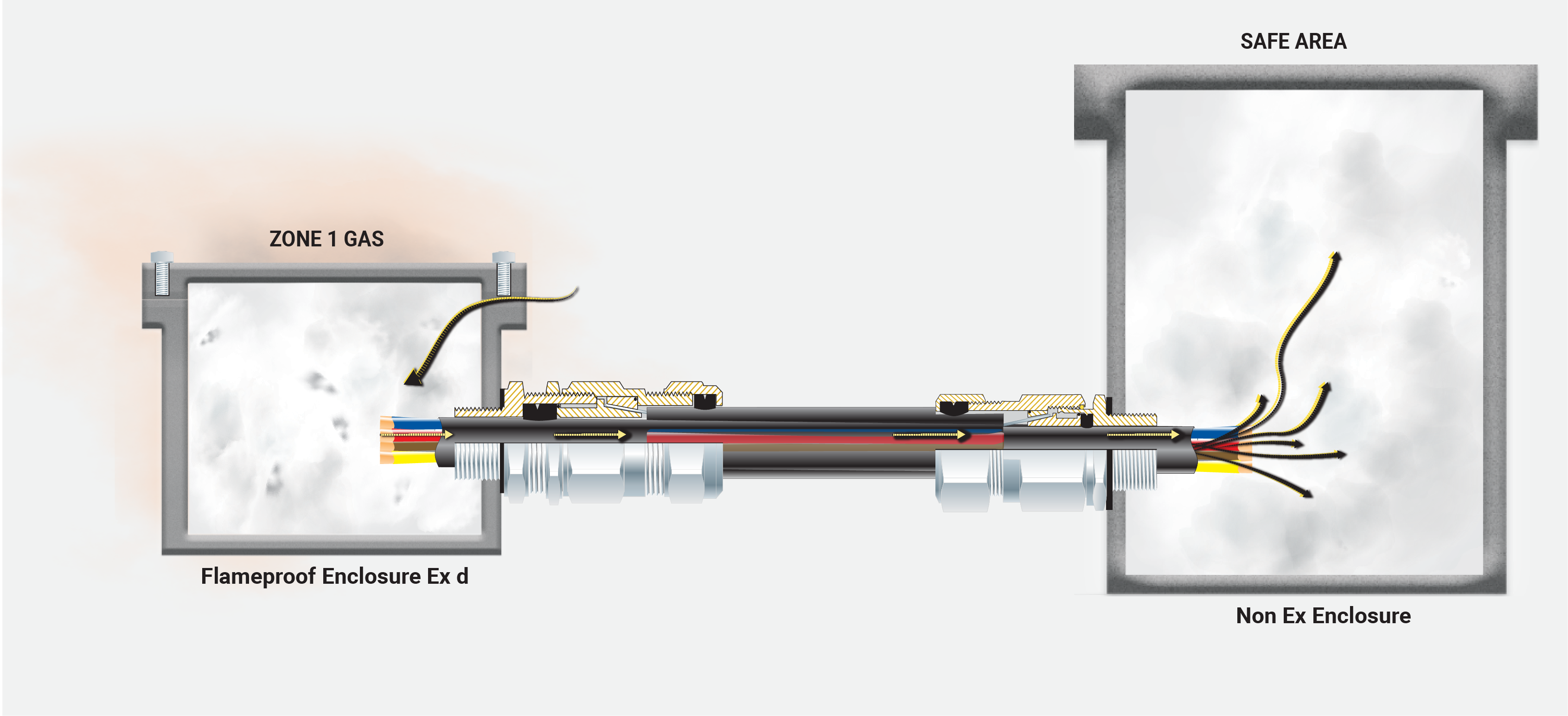

- cable entry devices having an Ex Equipment certificate and complying with IEC 60079-1, and selected in accordance with the flow chart”. Conventional flame-proof Ex d cable glands with seals are designed primarily to retain the explosive pressure within an Ex d enclosure and prevent the passage of hot gasses through the cable entry to the surrounding atmosphere. The design of such cable glands relies on elastomeric seals sealing around the bedding of the filled cable to perform this function.

If it has been established that cables are not effectively filled, substantially round, and are hygroscopic, hot gasses and the pressure produced by an explosion within an Ex d enclosure can bypass the protective elastomeric seals of a conventional Ex d gland. These hot gases can be forced down the interstices of unfilled cable, resulting in potential damage to the cable and/or equipment. The use of barrier glands effectively blocks these explosive gases from migrating down the interstices of unfilled cable.

Barrier Glands are also required for the following equipment:

Ex p

Pressurized Equipment may also necessitate the use of Barrier Glands. Where necessary, to prevent a drop in pressure, the ingress of combustible gas or vapour by diffusion, or to prevent leakage of protective gas, wiring systems shall be sealed. If cables are not compact and filled, barrier glands should be used.

Ex nR

IEC 60079-14 Clause -7.5.8 Cable entry device for Type of Protection “nR”:

“The selection of cable entry devices for restricted-breathing “nR” enclosures shall be such as to maintain the restricted-breathing properties of the enclosure. Where the cable used is not part of the Ex Equipment Certificate or manufacturer’s instruction and is not effectively filled, it might be necessary to use a cable entry device or other method (for example resin joint, shrinking tube) which seals around the individual conductors of the cable to maintain the restricted breathing characteristics of the enclosure.”

GAS MIGRATION THROUGH CABLE ON SITE

EXPLOSIVE GASSES THROUGH UNFILLED CABLE

UNFILLED CABLE

FLAME TRANSMISSION TEST

Time Consuming Installation

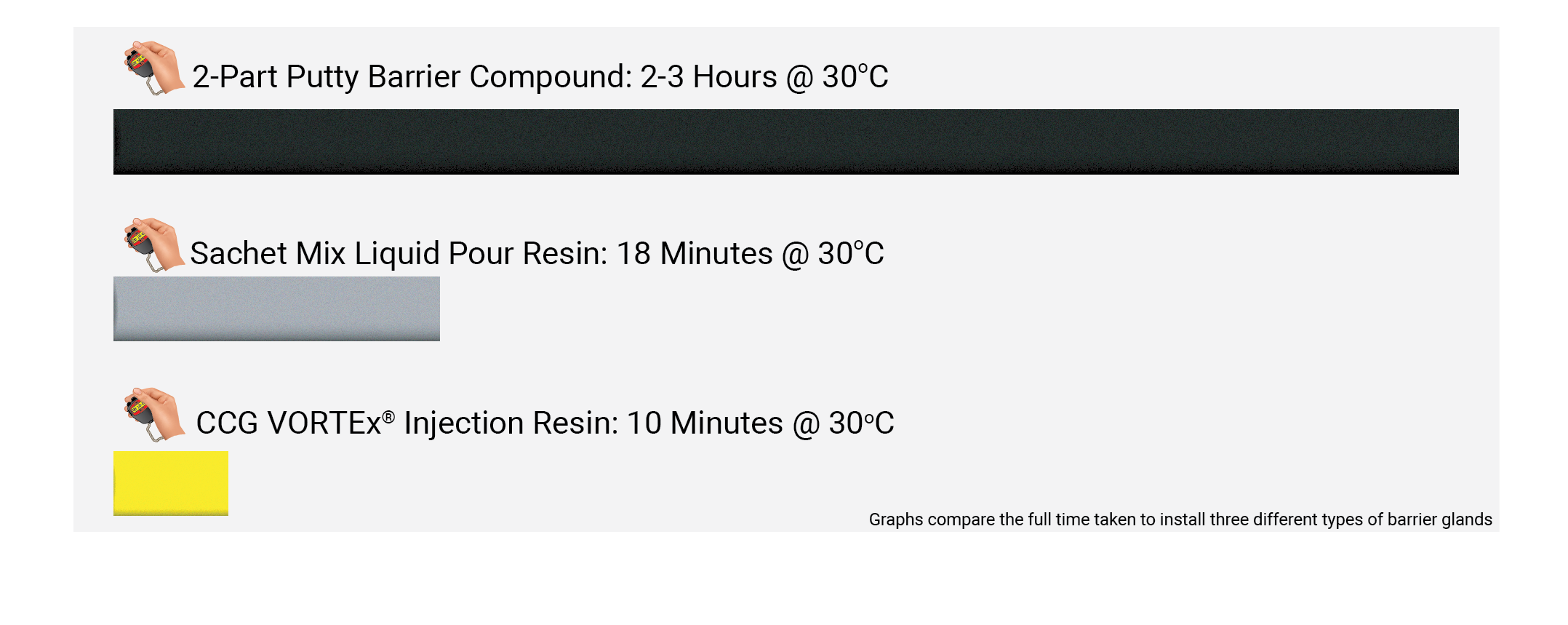

For several years, installers in hazardous areas have been relying on barrier glands with a two-part epoxy-based putty as a way to stop explosive gases and liquids from diffusing down unfilled cables.

The problems with the two-part putty-based compound have always been the time taken to mix and then insert and pack the putty between the cable voids and into the barrier gland chamber.

The mixing process, which can take several minutes depending on the amount of putty needed, has always been subjective because the putty is only truly combined when the two parts are hand-moulded into an “even colour.”

The insertion of the putty between the individual cores of the multi-core cable is not only time-consuming, but there could be additional risks in that the putty may not have been inserted and packed correctly, which results in the potential for voids and gaps for gas or liquids to migrate through.

In addition, once the putty has been inserted between the cable cores and the barrier chamber, the time taken for the putty to harden can be up to several hours.

Barrier glands have always required unique skills from installers and extra attention from inspectors due to these premixing and installation issues.

Recently, a two-part liquid pour resin system was re-introduced into the market that, whilst being effective in filling all the gaps and interstices in a cable, its two-part sachet mixing system does not adequately address the time taken and risks involved during the mixing process. The sachet mixing process is still very subjective and inaccurate, especially at varying temperatures, and can result in the resin setting either too quickly or not setting properly at all.

CCG has an Accurate Quick and Safe Solution

CCG’s VORTEx Barrier Gland

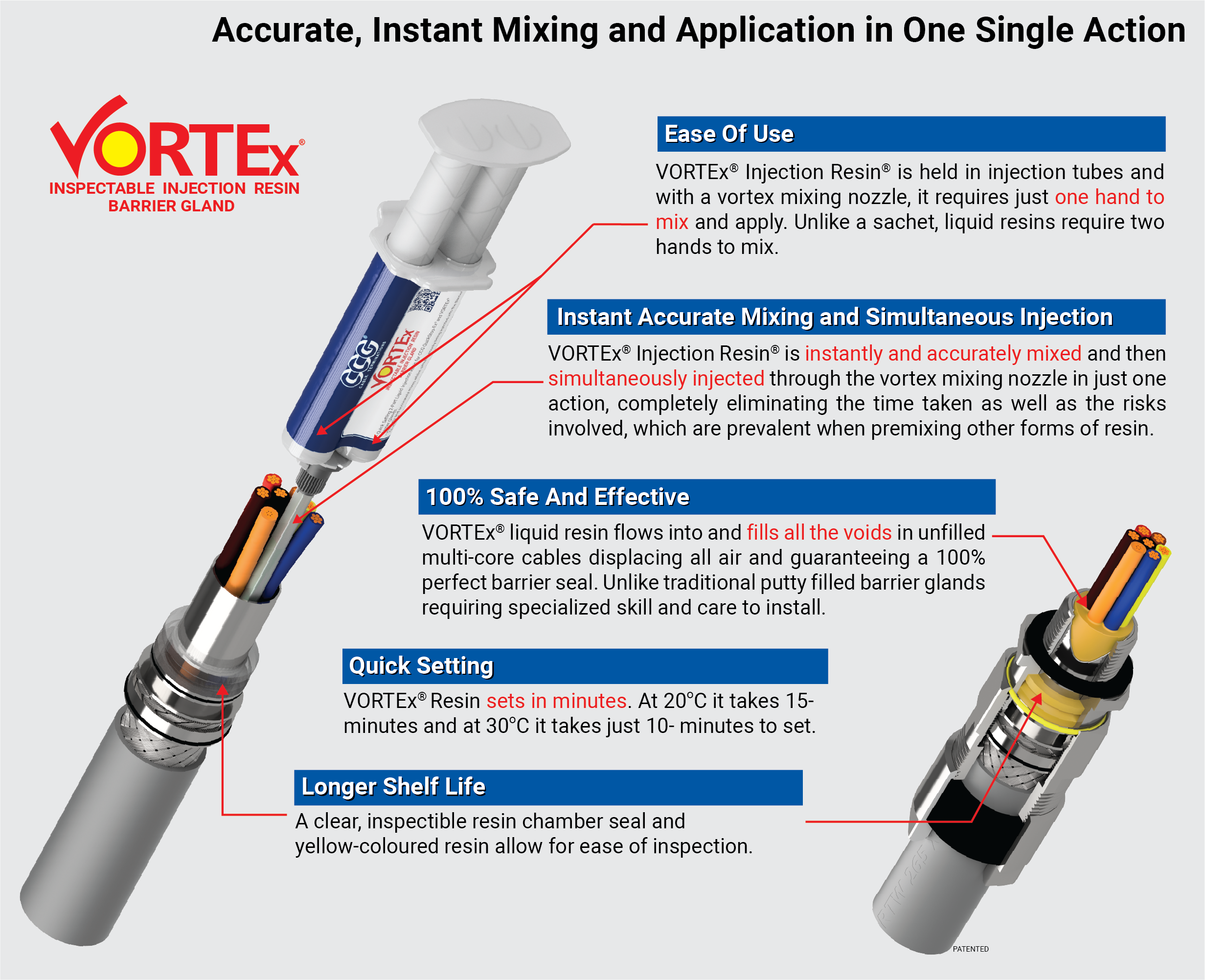

CCG’s VORTEx® Barrier Gland with an instant mixing, injecting resin has all but eliminated the hassles surrounding the preparation, mixing, and application of compounds/resins in Barrier Glands. The VORTEx® Injection Resin system is instantly and 100% accurately mixed whilst being simultaneously injected into the barrier gland in one single action. This reduces the installation time and gives increased confidence in the installation compared to the epoxy putty or sachet mix liquid pour resins.

The Injection resin flows into all the cable voids and interstices, completely filling the cable end. This forms a 100% barrier to any migration of explosive gases or fluids down the inside of an unfilled hygroscopic cable. VORTEx® barrier glands are tested and fully comply with the latest IEC Ex standards and installation codes of practice.