Hazardous Areas - CCG

A hazardous area is one in which there is a potential for an explosion of gases, vapours, mists or dust or a combination of these, during the operation of a plant or process, such as petrochemical plants, offshore oil rigs, fuel filling stations, timber mills, coal mines, flour mills, paint spray booths, sewerage treatment plants, hospitals, explosive magazines etc. Special precautions must be taken for the design, manufacture, installation and use of equipment in such hazardous areas.

This is covered in the following Standards:

• IEC 60079-14

• EN 60079-14

• AS/NZS 60079-14

• SANS 60079-14

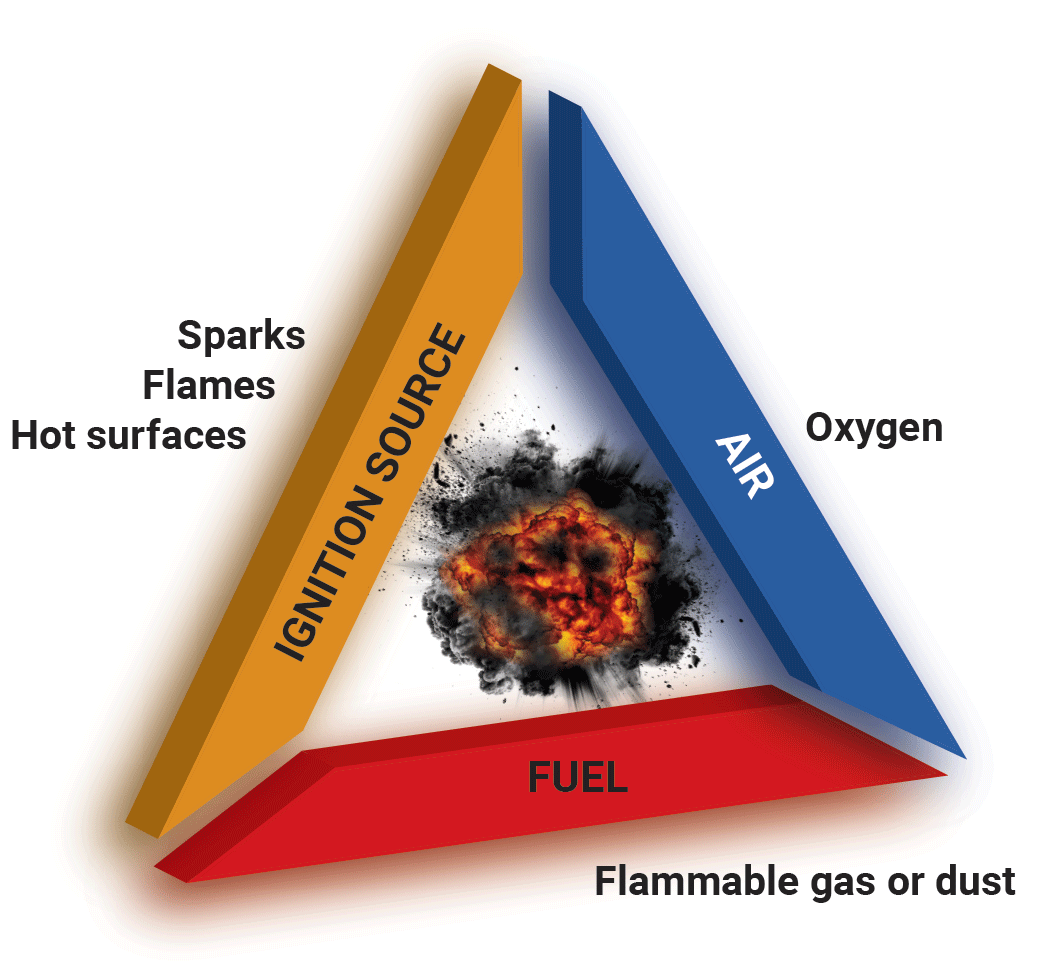

In order to prevent an explosion at least one of the 3 elements must be controlled or if possible removed.

This can be by:

- Reducing the number of flammable gases or dust.

- Preventing the formation of an explosive atmosphere (remove air and or oxygen).

- Avoiding ignition sources.

If an explosion cannot be prevented then measures must be taken to control the explosion so as not to cause damage to life or property.

These measures are:

- Contain the explosion.

- Isolate the explosion away from property and personnel.

- Suppress the explosion actively or passively.

- Vent or relieve the explosion.